Crabby

NJRC Member

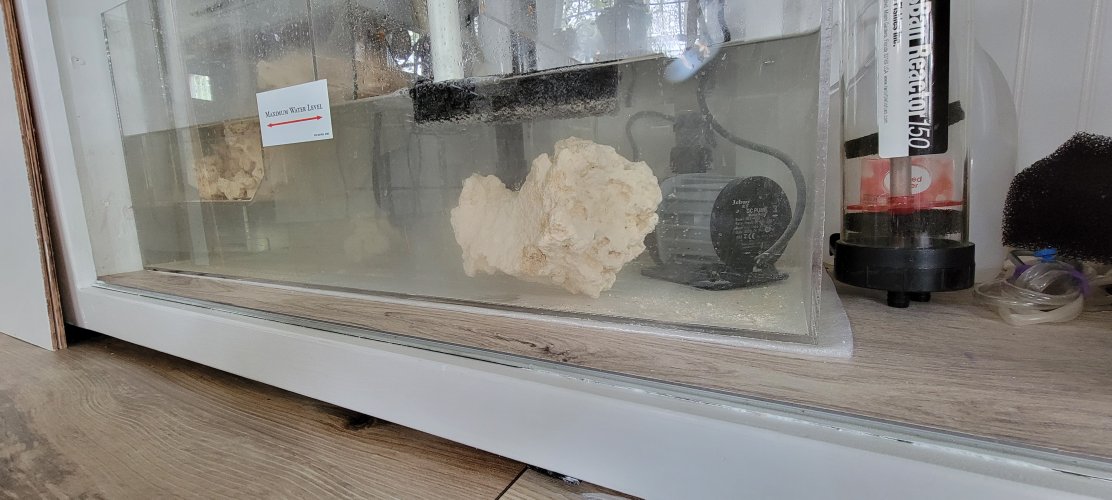

Hi all, I have a question. Can super glue be used to bond Lexan to Acrylic? I plan on reworking this old sump to increase refuge in middle, and lessen the left side which will only be drain + skimmer area.

I've used super glue to bond Lexan together and it's a strong bond. I have sheets of Lexan so it'll be Lexan to Acrylic which I believe will work. I'm not sure about Weld On working with the Lexan since it's polycarbonate. Any input, experience will be greatly appreciated.

TIA!

I've used super glue to bond Lexan together and it's a strong bond. I have sheets of Lexan so it'll be Lexan to Acrylic which I believe will work. I'm not sure about Weld On working with the Lexan since it's polycarbonate. Any input, experience will be greatly appreciated.

TIA!