This issue with the Apollo light was without question a heat transfer problem. What also could have contributed to the LED failure was the quality of the blue LEDs.

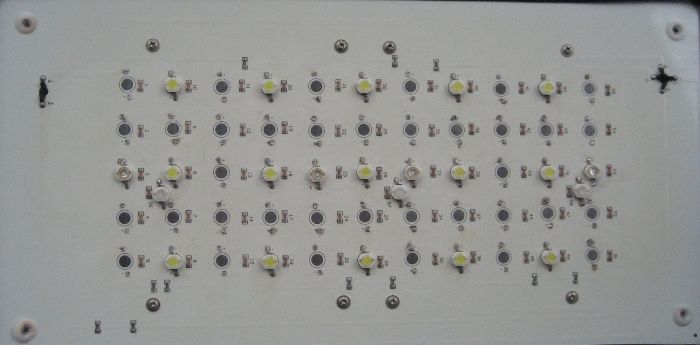

The white and red LEDs survived unscathed. All the blues on either circuit were fried.

The LEDs were solder/attached to the flat aluminum plate. There was thermal grease used between the LED and aluminum plate.... a very small amount. This aluminum plate was then attached to two finned aluminum heat exchangers on the top side. Between these pieces of aluminum was thermal grease as well, but was not continuous. Sorry it's out of focus, but you can still see the white thermal grease on the back side of one of the finned cooling blocks....and there are "open" spots.

Now what also rips my shorts is that, other than the fans themself and the moonlight driver, nothing has a label or identification marking on them......specifically, the two main LED drivers, and the small driver for the three fans.....nothing to identify how many volts and/or output amperage. This has made finding a replacement fan much more difficult. If I knew the output amperage I could potentially get a better fan (more flow), because, for the most part, increase power consumption means increased amount of air flow (CFM). So right now, not knowing the information about the power supply, I'm stuck picking a 0.1A fan. I'd prefer more, but can't take the chance.

The white and red LEDs survived unscathed. All the blues on either circuit were fried.

The LEDs were solder/attached to the flat aluminum plate. There was thermal grease used between the LED and aluminum plate.... a very small amount. This aluminum plate was then attached to two finned aluminum heat exchangers on the top side. Between these pieces of aluminum was thermal grease as well, but was not continuous. Sorry it's out of focus, but you can still see the white thermal grease on the back side of one of the finned cooling blocks....and there are "open" spots.

Now what also rips my shorts is that, other than the fans themself and the moonlight driver, nothing has a label or identification marking on them......specifically, the two main LED drivers, and the small driver for the three fans.....nothing to identify how many volts and/or output amperage. This has made finding a replacement fan much more difficult. If I knew the output amperage I could potentially get a better fan (more flow), because, for the most part, increase power consumption means increased amount of air flow (CFM). So right now, not knowing the information about the power supply, I'm stuck picking a 0.1A fan. I'd prefer more, but can't take the chance.