arvin

NJRC Member

Hello,

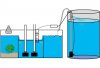

I am trying to setup an auto top off system. See the pic below:

The blue container holds the fresh water from the ro/di unit. I use a Mag 5 pump to push the water up to the sump. I installed this only a couple of days ago and have not setup the sensors yet. I am manually operating the pump currently. Last night when I ran this pump to do top off, the water kept pouring even after the pump was off. I started panicking and tried to pull the pump out of the container. I couldn't since it was a hard PVC connection. Next I tried to close the outlet in the sump with my hand tightly. That's when the water stopped. Any idea why this would happen? And how do I plumb this such that the water stops when the pump is turned off?

As the pic shows this is not a gravity feed. The sump is on the same level as the blue container. The days before yesterday the water stopped just fine only yesterday this happened and now I am too scared to try one more time.

Any help is greatly appreciated!

I am trying to setup an auto top off system. See the pic below:

The blue container holds the fresh water from the ro/di unit. I use a Mag 5 pump to push the water up to the sump. I installed this only a couple of days ago and have not setup the sensors yet. I am manually operating the pump currently. Last night when I ran this pump to do top off, the water kept pouring even after the pump was off. I started panicking and tried to pull the pump out of the container. I couldn't since it was a hard PVC connection. Next I tried to close the outlet in the sump with my hand tightly. That's when the water stopped. Any idea why this would happen? And how do I plumb this such that the water stops when the pump is turned off?

As the pic shows this is not a gravity feed. The sump is on the same level as the blue container. The days before yesterday the water stopped just fine only yesterday this happened and now I am too scared to try one more time.

Any help is greatly appreciated!