So with my new build I have 2 mp40 pumps to use on it. Got them set up and they are loud! Now I know form my mp10s I need to adjust to find a sweet spot. Yes, I found the same applies to the 40s but when I rev up past 50% the vibrational hum is unacceptable. I see the wet side disassembles for ease of cleaning and I have fiddled to make sure it's all secure. While one pump is used and the other new from rebate sale offered in Dec. they both do exactly the same thing in regards to noise. I measured the glass and it's 5/8 thickness and adjusted the spacer for this. Any ideas? Is there some break in period? I'm thinking of going to use my mp10s as they hold fine and while not as much flow per unit! I have 3 on my 55 and like I said more silent even at max.

-

Folks, if you've recently upgraded or renewed your annual club membership but it's still not active, please reach out to the BOD or a moderator. The PayPal system has a slight bug which it doesn't allow it to activate the account on it's own.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mp40s are loud

- Thread starter Zippy69

- Start date

Are these new or used?

The first thing I'd try is setting the thickness to 1/2 inch. It pulls the dry side back a touch more and therefore puts less strain of the lateral pull on the bearings. These bearing were not designed for lateral stress.

The next thing is aligning them to the wet side. I put my ear on the glass and slightly move the dry side around until I have the least amount of noise.

And finally, try not to run them wide open. Causes for more noise and will wear the bearing prematurely.

If this fails, and assuming they are used (and out of warranty), you might want to think about replacing the bearings. It's relatively easy (but a bit scary cutting into a 400+ dollar powerhead), and the bearing only run around $20 or so.

EDIT TO ADD:

HERE is a link that might be of interest if you end up replacing the bearings. This is my experience of doing this on an MP10.

The first thing I'd try is setting the thickness to 1/2 inch. It pulls the dry side back a touch more and therefore puts less strain of the lateral pull on the bearings. These bearing were not designed for lateral stress.

The next thing is aligning them to the wet side. I put my ear on the glass and slightly move the dry side around until I have the least amount of noise.

And finally, try not to run them wide open. Causes for more noise and will wear the bearing prematurely.

If this fails, and assuming they are used (and out of warranty), you might want to think about replacing the bearings. It's relatively easy (but a bit scary cutting into a 400+ dollar powerhead), and the bearing only run around $20 or so.

EDIT TO ADD:

HERE is a link that might be of interest if you end up replacing the bearings. This is my experience of doing this on an MP10.

Should both be still under....one at the least.Are these new or used?

One brand spanking new, the other used manufacture date oct2013. So both have little to no wear and tear

The first thing I'd try is setting the thickness to 1/2 inch. It pulls the dry side back a touch more and therefore puts less strain of the lateral pull on the bearings. These bearing were not designed for lateral stress.

Thanks I will try this

The next thing is aligning them to the wet side. I put my ear on the glass and slightly move the dry side around until I have the least amount of noise.

Yup did that, it's the same for the 10s there is a sweet spot to listen for

And finally, try not to run them wide open. Causes for more noise and will wear the bearing prematurely.

Was not going to, but wanted to see it in reef rest mode

If this fails, and assuming they are used (and out of warranty), you might want to think about replacing the bearings. It's relatively easy (but a bit scary cutting into a 400+ dollar powerhead), and the bearing only run around $20 or so.

Thanks fir the input Paul I'll try the 1/2 inch setting.

One other thought....do you have that thin rubber gasket between the dryside and the glass?

One other thought....do you have that thin rubber gasket between the dryside and the glass?

Yes, should I not?

Yes, should I not?

Yes, definitely want that little piece of rubber.

Why does 1/2 work better?

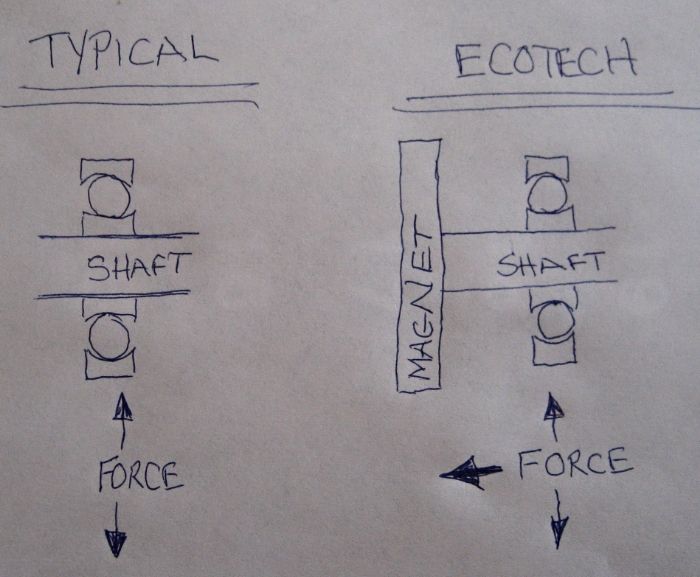

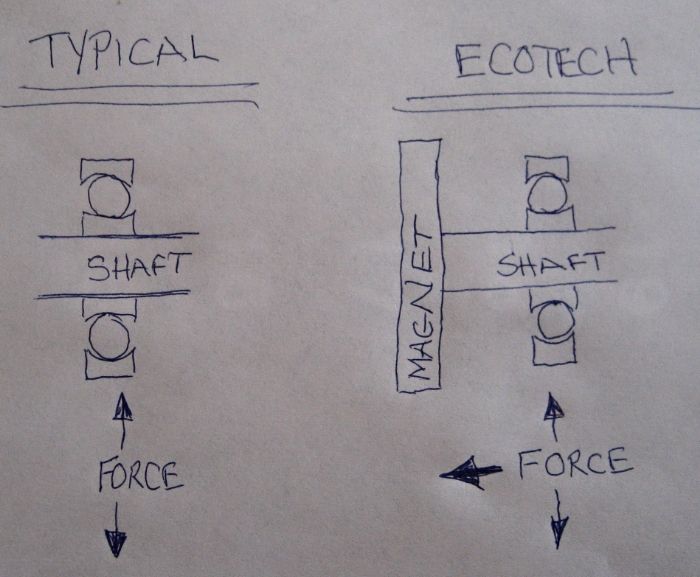

This is my guess......the bearing are not made for lateral forces....they are fishing reel bearings....they just like to spin. When applying lateral force (in our case, from the magnets pulling towards each other) the bearings are being "pulled" causing them to now run on the side portions of the bearing case, and not in the planar races. When grinding against the sides of the bearing case, it makes noise...and begins to wear, eventually causing them to get loud. By using the 1/2 inch setting, it separates the magnets slightly more, putting a little less stress on the bearings.

Interesting Paul. My MP40 is usually almost silent, but occasionally a large turbo might knock it off center slightly and I hear some vibrations, especially when it's running at full speed. I'll try changing the setting to 1/2" and see if that makes a difference.

So when are we going to make a sub forum called "ask redfishbluefish"? Paul always has the answer

Sent from my SGH-M919 using Tapatalk

Sent from my SGH-M919 using Tapatalk

So when are we going to make a sub forum called "ask redfishbluefish"? Paul always has the answer

Sent from my SGH-M919 using Tapatalk

Kyle you are too kind. But I only answer on a few topics that I know....DIY stuff and chemistry. I don't know anything about corals (I don't know what's in my tank), fish, music, movies, computers, phones (I don't own a cell phone...it's my wife's), wines (I'm Irish, there is no such thing as a bad wine), and way to many other things to mention. So actually I'm rather limited, and now that you've brought it up, sort of a boring person with limited interests.

With this particular OP's issue, I've ripped apart an MP10 to replace the bearings, so that makes me an expert.

Oh, and one more thing....I'm old.....I've been around the block a few times.

Here's my opinion on the bearings they use. I think the use cheep bearings bc they can make more money on replacing a $2 bearing for 100+ . IMO if I were them why wouldn't you want your product to last long not just a couple of years. They do make bearings that can take lateral pull much better . When I replace mine I'm going to get ceramic bearings take a load better and the noise lvl is a huge difference.

Here's my opinion on the bearings they use. I think the use cheep bearings bc they can make more money on replacing a $2 bearing for 100+ . IMO if I were them why wouldn't you want your product to last long not just a couple of years. They do make bearings that can take lateral pull much better . When I replace mine I'm going to get ceramic bearings take a load better and the noise lvl is a huge difference.

Don't be too quick on blaming the quality of the bearing. I used a good quality bearing (ABEC5), and still have some noise. Others have used the lowest quality bearings (ABEC 1), and haven't had a problem. And in regard to ceramic, i know it's long, but if you want to do this replacement, please read the RC POST.....and you'll see the ceramics might even be more of a problem???

Again, bottom line, I'm convinced it's the lateral force on the bearings that is making the noise....quality appears to not matter!

You are correct, when used as intended. A number of these ceramic bearing have ABEC 8 grading....very high quality. Please read the above post...and you will see that people who installed ABEC 8 ceramic bearings had noise problems. The problem is that they are taking a bearing designed for radial forces and now subjecting that bearing to lateral forces. I contend that it is this force that is causing the problem. These bearing were not designed to accept this force. Here is a fine looking cross-sectional drawing of the intended "typical" use of a bearing and the Ecotech example....hopefully this makes it a bit clearer.

If you find one that will fit that little motor, please let me know. This actually was my thought as well.....a tapered rollerbearing...or even a tapered ballbearing....I think either one would work.....if they existed that small!