DYIguy

NJRC Member

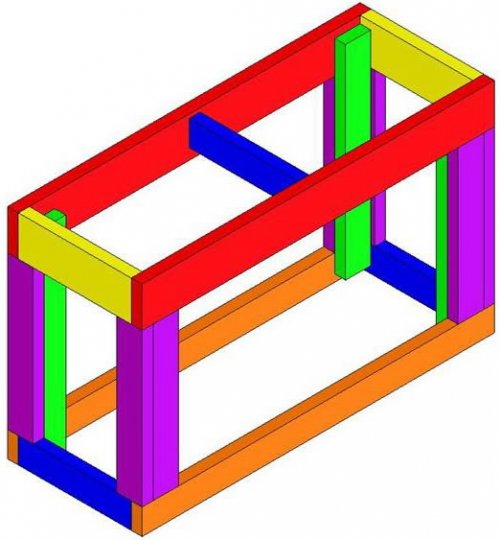

Picked up the tank today- almost gave it up thinking about the weight and moving it myself with the size- the 30 and 40 were no problem- the cube was a piece of cake. 2 associates put it on a cart and asked if I need help getting it into my car (?)- I joked that I have it under control and if it cracks while I'm loading it that I'll be be back in for another one- they just walked away- some guy in the lot helped me though. Time to look into building a stand- designs/ materials- this one may take some time- and I have to make room- it will end up where the 30l is ( which will be up for grabs- tank, hood and cabinet- free to me- free to you ) and there's a shelf that has to go with 50 years of pictures/ albums, memorabilia from 35 + cruises- will find a place for them- or recycle