Vortech’s overpriced powerheads are known for eating bearings on their dryside, usually evident in becoming very loud. If they are still under warrantee, no problem, you get a new dryside replacement. If they are out of warrantee, your choice was to buy a new dryside for mucho bucks……..until dahenley posted a DIY over on Reefcentral titled “Noisy Vortech DrySide FIX!!” So I can’t take credit for this, but wanted to post my experiences here on replacing the noisy bearings in an MP10. I’ll also be doing this soon for a noisy MP40 I have….but this post is all MP10

I used the above RC post to learn about how to do the replacement, as well as purchasing what I thought were the best bearings for the MP10. You wouldn’t believe all the different types and qualities of bearings there are. Anyway, from what had been published, I came to the conclusion that the BOCA bearing SMR147-ZZ #5 at $8.95 each gave you the best bang for the buck. With free shipping, for $17.90 for two bearing, I’ll hopefully have a better-than-new dryside….versus a new dryside from Vortech for $106. I’ve since seen additional posts over on RC where a poster has had problems with these particular Boca bearings. So it’s still a puzzle on what the best bearing is or if there is something else going on.

The second little tidbit that helped ease me into doing this DIY were two YouTube videos that showed how to pull apart a Vortech pump, and how to put it back together. Here are those two videos:

Pulling apart a Vortech

Putting a Vortech back together

Now here are my experiences:

OPENING THE VORTECH

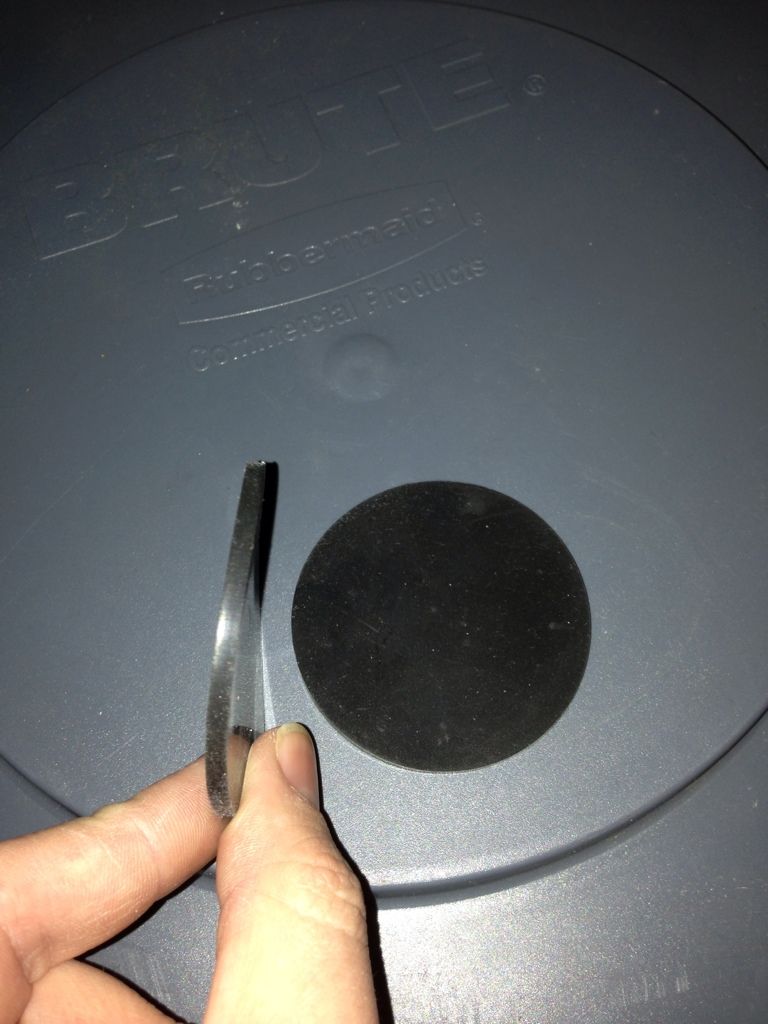

This is the scary part of the rebuild….you will be potentially defacing the dryside…and it wasn’t real clear from the write up, and certainly not the video, in how to go about this. They said pry it off. Well prying worked for me about half way around the pump. I started with a fixed blade scalpel (this is an antique, and no longer available). I choose this as my first tool of choice because not only was it sharp, to help cut, but also strong enough to pry as well. But again, half way around, prying became difficult and I was doing damage to the plastic. So my next attack was with a utility knife with a new blade. I kept running this back and forth in the grove until it cut all the way through. I continued this cutting method the rest of the way around the pump. All this cutting and prying took about 45 minutes or so. Here are the two tools I used for that:

One more thing….before starting to cut this end piece off, I put alignment marks in this piece so that when I re-assembled it, the end piece would go back in exactly the same position. Two little notches were made in-line with the wire cutout, to use as an alignment point.

Once this end piece was cut off, I used the RC instructions and video to continue disassembling the pump. The allen wrench that is needed is a 2 mm wrench. The pump easily opened up and the rotor easily slipped out. Be careful not to loose the three washers in the far end of the stator portion.

REMOVAL OF THE OLD BEARINGS

Now with the removal of the old bearings, the video showed how to use a builder’s square to pop the bearings off. I’ve got to assume that video was done on an MP40, because when I went to slide my builder’s square between the bearing and rotor magnet, it wasn’t even close to fitting.

So the way I pulled off the old bearings was to use my vise on the outer bearing by very lightly clamping down on the bearing and tapping a hammer on a wood dowel that was in contact with the rotor shaft. With the inner bearing, the vise couldn’t hold it tight enough, so I lightly clamped this bearing in a pair of vise grips and then did the same tapping thing.

INSTALLING THE NEW BEARINGS

If you read all the posts over on RC you will see a number of folks who still had noisy Vortechs after installing new bearings. It’s a puzzle. But one of my guesses is that the bearings aren’t slide on all the way and now cause for excessive lateral forces on the bearings…..which causes the noise. Again, this is a big guess on my part. So I wanted to make sure my bearings were driven all the way “home.” So the rotor went into the freezer for a couple hours while the bearings rested on one of the hot radiators in the house… (forced hot water in an older house with cast iron radiators….and frigid temperatures helped with a real hot radiator) In addition, I drilled two pieces of scrap lumber with a 9/32” drill. This is oh-so-slightly larger than the rotor shaft. I used these blocks to very lightly tap the bearing “home” using a hammer.

The rest of the reassembly was uneventful. I attached the cut-off end piece with six or seven dabs of cyanoacrylate glue. I was fortunate in that the rebuild is now quiet. Dance

I used the above RC post to learn about how to do the replacement, as well as purchasing what I thought were the best bearings for the MP10. You wouldn’t believe all the different types and qualities of bearings there are. Anyway, from what had been published, I came to the conclusion that the BOCA bearing SMR147-ZZ #5 at $8.95 each gave you the best bang for the buck. With free shipping, for $17.90 for two bearing, I’ll hopefully have a better-than-new dryside….versus a new dryside from Vortech for $106. I’ve since seen additional posts over on RC where a poster has had problems with these particular Boca bearings. So it’s still a puzzle on what the best bearing is or if there is something else going on.

The second little tidbit that helped ease me into doing this DIY were two YouTube videos that showed how to pull apart a Vortech pump, and how to put it back together. Here are those two videos:

Pulling apart a Vortech

Putting a Vortech back together

Now here are my experiences:

OPENING THE VORTECH

This is the scary part of the rebuild….you will be potentially defacing the dryside…and it wasn’t real clear from the write up, and certainly not the video, in how to go about this. They said pry it off. Well prying worked for me about half way around the pump. I started with a fixed blade scalpel (this is an antique, and no longer available). I choose this as my first tool of choice because not only was it sharp, to help cut, but also strong enough to pry as well. But again, half way around, prying became difficult and I was doing damage to the plastic. So my next attack was with a utility knife with a new blade. I kept running this back and forth in the grove until it cut all the way through. I continued this cutting method the rest of the way around the pump. All this cutting and prying took about 45 minutes or so. Here are the two tools I used for that:

One more thing….before starting to cut this end piece off, I put alignment marks in this piece so that when I re-assembled it, the end piece would go back in exactly the same position. Two little notches were made in-line with the wire cutout, to use as an alignment point.

Once this end piece was cut off, I used the RC instructions and video to continue disassembling the pump. The allen wrench that is needed is a 2 mm wrench. The pump easily opened up and the rotor easily slipped out. Be careful not to loose the three washers in the far end of the stator portion.

REMOVAL OF THE OLD BEARINGS

Now with the removal of the old bearings, the video showed how to use a builder’s square to pop the bearings off. I’ve got to assume that video was done on an MP40, because when I went to slide my builder’s square between the bearing and rotor magnet, it wasn’t even close to fitting.

So the way I pulled off the old bearings was to use my vise on the outer bearing by very lightly clamping down on the bearing and tapping a hammer on a wood dowel that was in contact with the rotor shaft. With the inner bearing, the vise couldn’t hold it tight enough, so I lightly clamped this bearing in a pair of vise grips and then did the same tapping thing.

INSTALLING THE NEW BEARINGS

If you read all the posts over on RC you will see a number of folks who still had noisy Vortechs after installing new bearings. It’s a puzzle. But one of my guesses is that the bearings aren’t slide on all the way and now cause for excessive lateral forces on the bearings…..which causes the noise. Again, this is a big guess on my part. So I wanted to make sure my bearings were driven all the way “home.” So the rotor went into the freezer for a couple hours while the bearings rested on one of the hot radiators in the house… (forced hot water in an older house with cast iron radiators….and frigid temperatures helped with a real hot radiator) In addition, I drilled two pieces of scrap lumber with a 9/32” drill. This is oh-so-slightly larger than the rotor shaft. I used these blocks to very lightly tap the bearing “home” using a hammer.

The rest of the reassembly was uneventful. I attached the cut-off end piece with six or seven dabs of cyanoacrylate glue. I was fortunate in that the rebuild is now quiet. Dance

)

)